Packaging is a prime opportunity to attract consumer attention and communicate brand identity. To create eye-grabbing graphics, packaging companies must rely on high-quality printing processes. Offset printing is a cornerstone technique that produces those desired results. With offset printing for packaging, companies can create vibrant, colorful, and detail-oriented designs that leave their products standing out on shelves and resonating with target audiences.

What Is Offset Printing?

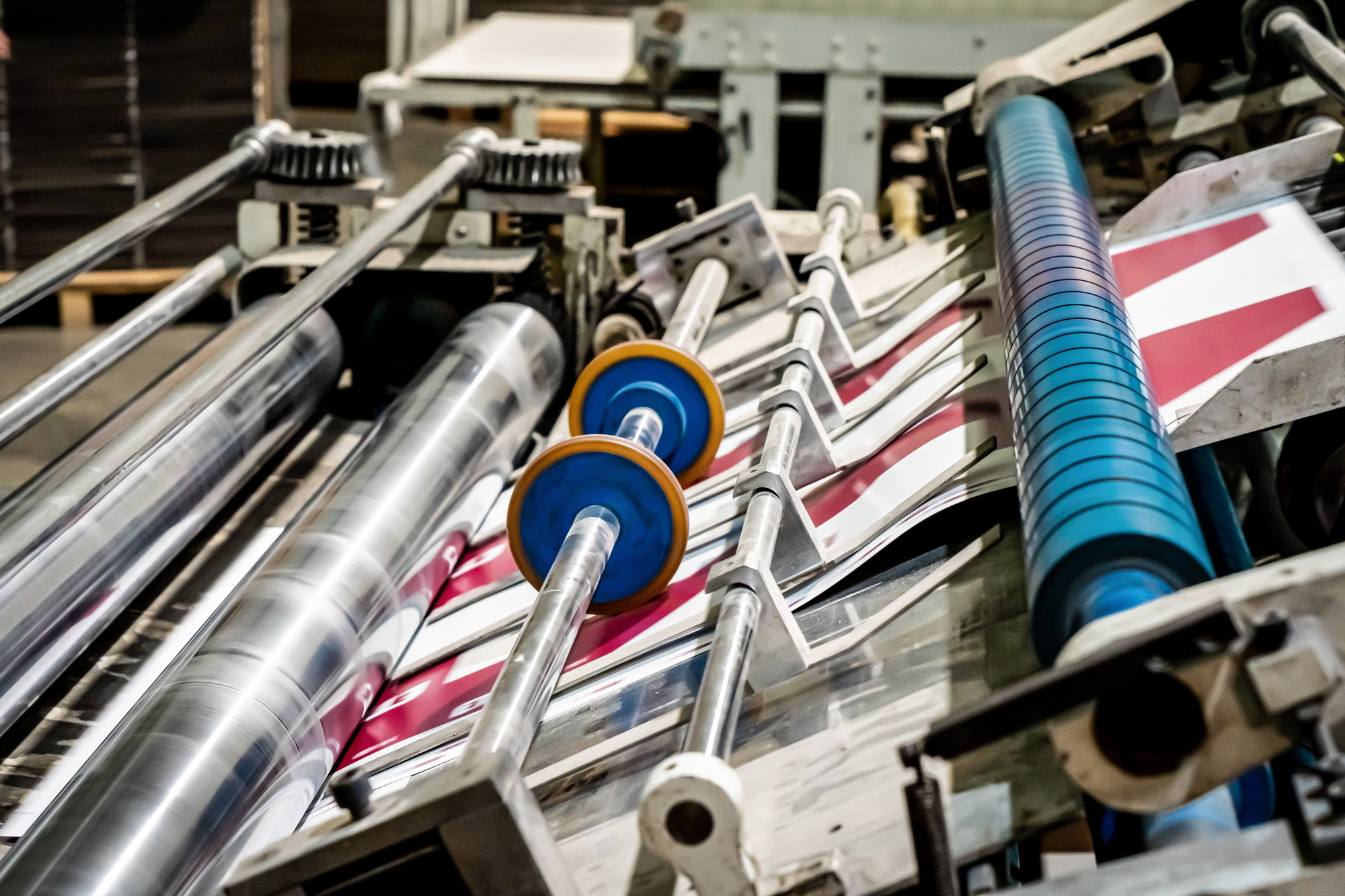

Offset printing is a commonly used technique that involves transferring an inked image onto a rubber printing blanket before transferring the final impression onto a surface, such as packaging material. Metal printing plates are etched with a specific design or image to be applied to packaging. The etched area accepts ink, while the non-etched accepts a film of water. As the printing blanket rolls over the metal plate, it picks up the inked image and transfers the design onto the packaging surface. Packaging materials then pass through a drying system to ensure the ink design sets properly.

Benefits of Offset Printing

Offset printing is the gold standard for product packaging because it offers:

- Superior image quality: Companies can expect clear images, clean lines, precise typography, and rich, accurate colors on their packaging.

- Scalability: Offset printing is cost-effective for large-volume print runs, even with complex designs.

- Consistency: Color matching and image reproduction remain uniform throughout the entire print run.

Offset Printing vs Digital Printing

Digital printing is another technique used in packaging design. It involves using a high-resolution digital file and printing it directly onto materials. Think of this process as similar to that of a copier. Though digital printing produces similar quality results to offset printing, it does have setbacks. Digital printing doesn’t have a color range as wide as offset printing. It’s also not a cost-effective option for large orders.

Offset Printing at MOD-PAC

At MOD-PAC, we only use offset printing processes. We hold a G7 Master Qualification, demonstrating our commitment to only the highest quality and standards for packaging printing. In recent years, we’ve invested heavily in our range of advanced Heidelberg presses and the latest color management spectrophotometers and densitometers. Our in-house plate-making capability provides the fastest response times and repeatable, precise results. We also perform copy checks at every stage of the printing process to ensure consistent quality.