Packaging manufacturing companies rely on a full fleet of tools and equipment to create the high-quality custom packaging their customers expect. Die tooling is one of the most crucial aspects of creating custom paperboard packaging. The die tooling process is essential for producing unique packaging cutouts and adhering to tight lead times. While some companies choose to outsource these manufacturing processes, MOD-PAC maintains die tooling in-house to ensure the highest quality packaging for every customer.

What Is Die Tooling?

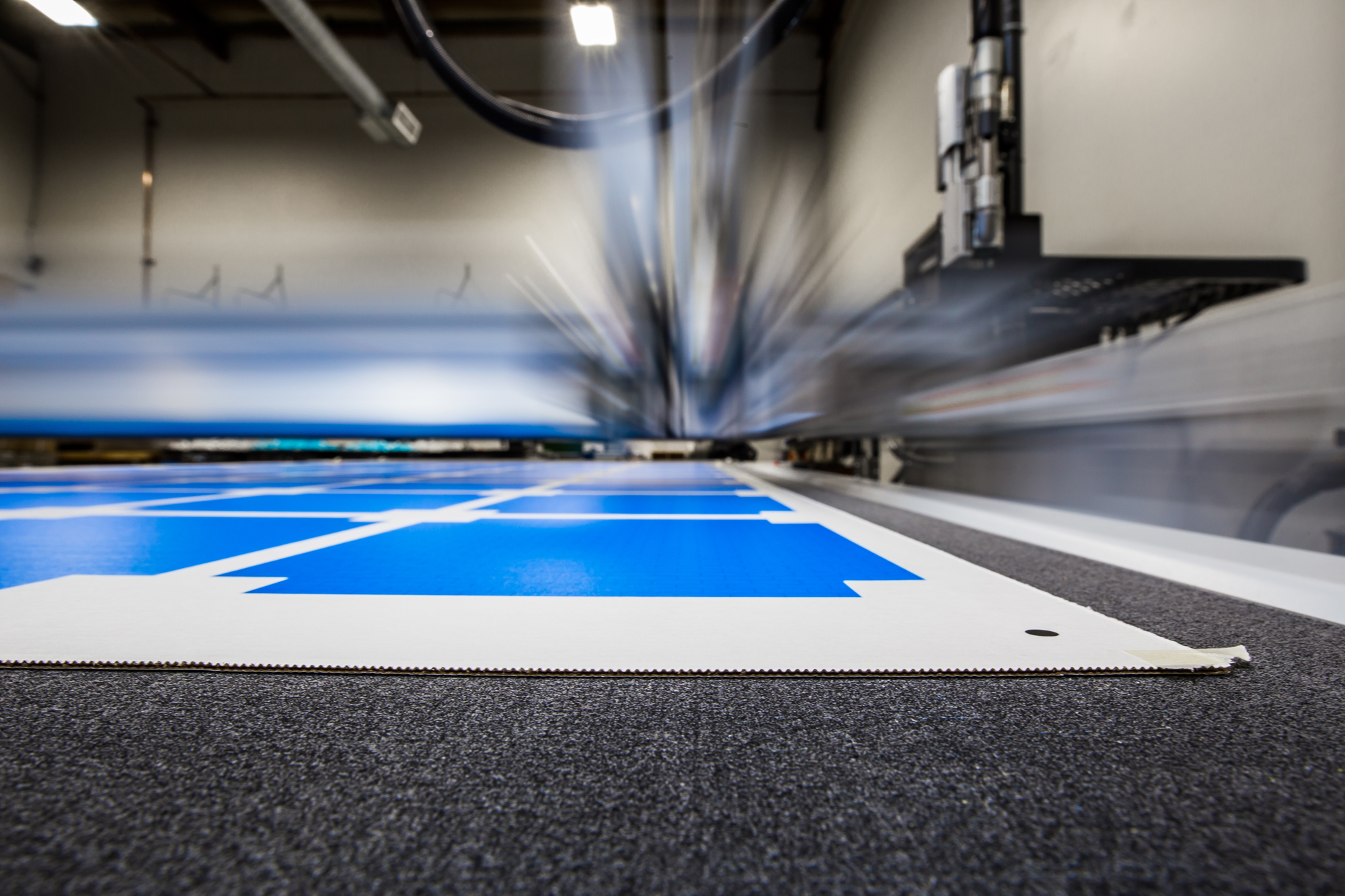

In the custom packaging industry, die tooling refers to the process of using tools called dies to cut, shape, and form packaging materials. This technique allows packaging manufacturers to create a custom die that replicates a precise, consistent template across a full run. By using dies, manufacturers ensure every packaging component is cut and formed to exact specifications.

Die Cut Packaging Process

The first step in using a die cut for printing is to create the die. Manufacturers work with customers to understand the desired dimensions and other key structural details. Layouts and templates are created using these metrics. The design will also include cutting and folding lines, perforations, windows, or slots as needed for the customer’s specific design. Once the design is finalized, a custom die is made from steel and mounted onto a die-cutting machine where production can begin. During the die-cutting process, paperboard sheets are fed into the machine, which uses the custom die to cut and score the material according to the design. This allows for mass production of fully uniform packaging, even when intricate shapes or features are part of the design.

Benefits of Die Tooling

Die tooling offers customers several important benefits, including:

Precision and consistency

Die tooling assures that every cut and fold is accurate for optimal integrity and functionality across the entire order quantity.

Efficiency

Die tooling makes mass product packaging production possible by allowing manufacturers to maintain fast lead times and offer repeatable results as needed for new orders with the same design requirements.

Customizability

Die tooling accommodates any dimension, shape, and branding requirements.

Cost-effectiveness

Though creating a die is an initial investment, the minimal material waste, high accuracy, and repeatability provided by die tooling ensure customers save on packaging costs in the long term.

Why MOD-PAC Handles Die Tooling Internally

Though some manufacturers outsource die tooling, MOD-PAC chooses to keep this process in-house. We’ve invested more than $30 million in technology in recent years to continue bringing our customers the best possible packaging solutions. In-housing die tooling provides us with several key advantages that are passed down to our customers:

Faster lead time

Internal processes mean our team doesn’t have to wait for outsourced dies or repairs to come in before packaging production can begin.

Precision and control

Our die boards are burned on laser cutters from CAD files generated internally for optimal precision and accuracy.

High quality

We use state-of-the-art equipment across our die tooling process. Our teams exert full control over these processes, allowing us to provide customers with top-notch packaging solutions and unmatched efficiency and quality.