Technological advancements are driving packaging innovation, allowing the industry to meet evolving consumer demands, improve operational efficiency, and align with global sustainability goals. Brands striving to balance functionality, environmental responsibility, and consumer engagement should look to new technology in packaging to help fulfill some of these needs. With its renewable inputs and adaptability, paperboard packaging is benefiting from cutting-edge advancements while developments in artificial intelligence and automation are reshaping the entire industry. For brands, working with innovative packaging partners and staying informed on trends is essential to delivering packaging solutions that meet practical needs and consumer expectations.

Sustainable Innovations and Packaging Technologies

Sustainability has been and will continue to be a cornerstone of modern packaging solutions. From choosing materials with a circular economy to creating biodegradable materials, industry leaders are finding new and improved ways to minimize environmental impacts while enhancing functionality through innovative sustainable packaging solutions.

High-Quality Recycled Paperboard

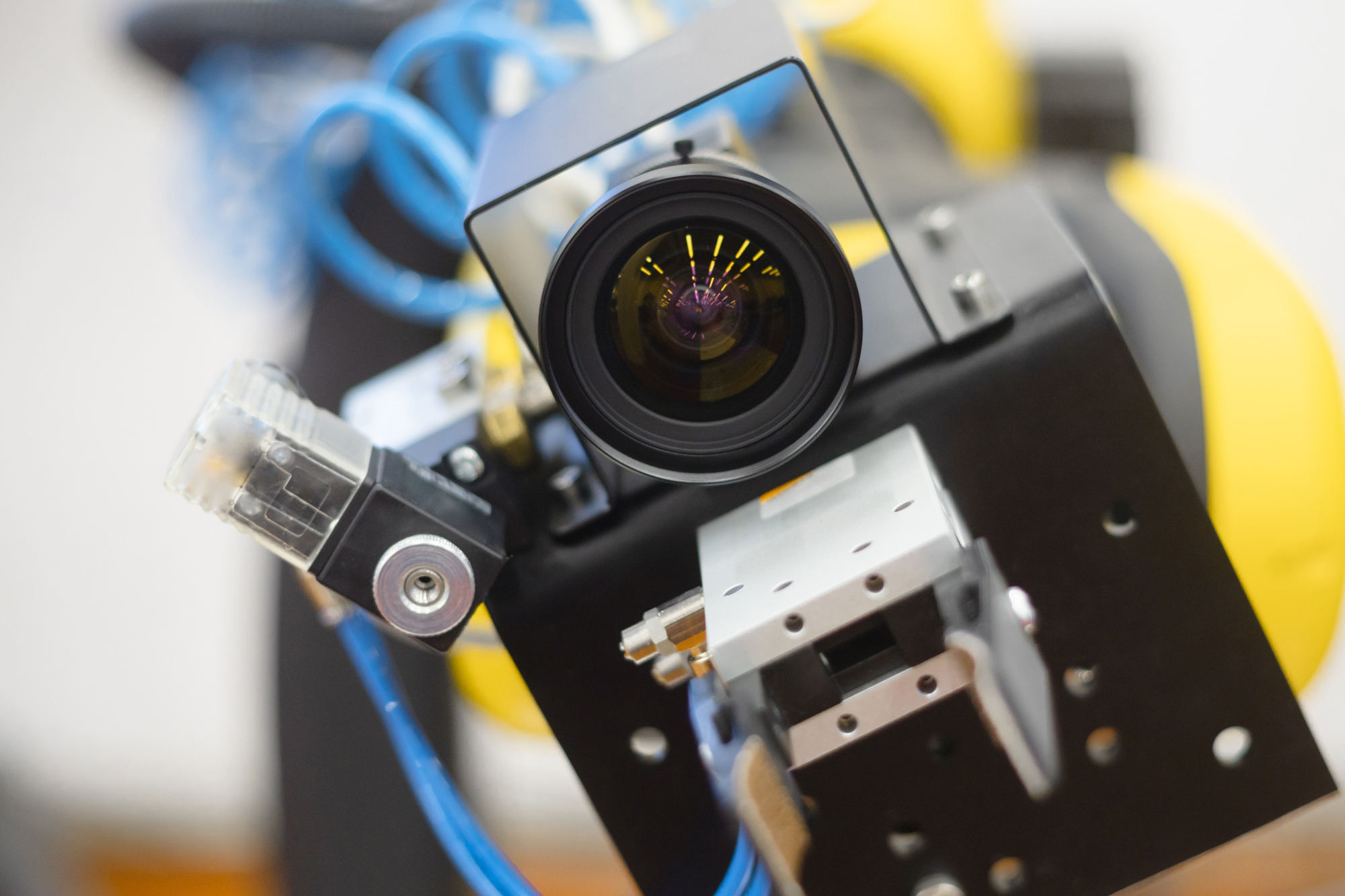

While paperboard is regularly recycled, elements like petroleum-based inks and plastic-based coatings limit recycling efforts. New processes and technologies are improving recycled paperboard quality and durability, creating a circular material economy. AI and robotics are at the forefront of these efforts. Modern recycling uses camera-equipped robots and AI algorithms to precisely identify and sort paperboard materials, which increases recycling efficiency and reduces the possibility of contamination. Deinking technologies with advanced flotation and washing systems have evolved to not only separate and remove ink and other contaminants from paperboard pulp but also restore the materials to a usable state.

Plant-Based and Biodegradable Coatings

Traditional plastic-based coatings are starting to be replaced by more sustainable alternatives. Some companies develop eco-friendly coatings derived from wood pulp and waste side streams, which are fully plant-based, recyclable, compostable, and biodegradable. Like traditional coatings, plant-based coatings still maintain proper protection by resisting moisture and grease contamination. Plus, these solutions are non-toxic and FDA-compliant.

Sustainable Inks

Traditional inks are often made from petroleum pigments. Aside from being a limited resource, the petroleum in these products also faces concerns regarding volatile organic compounds (VOCs), which many brands and packaging manufacturers are actively trying to reduce across their operations. Sustainable inks are a growing option. Soy-based or algae-based inks are considered some of the best options because they come from renewable natural sources, are recyclable, and reduce overall carbon footprint. These materials also carry color well, making them a strong candidate for traditional ink replacement.

Smart Packaging Technologies

Smart packaging solutions elevate packaging into an interactive, functional tool. Brands should consider integrating intelligent and active packaging technologies to improve product performance, protect contents, and enhance consumer engagement. Intelligent packaging provides real-time information about a product through QR codes and visual indicators to deliver additional product details like nutritional information or help consumers track freshness. Active packaging directly interacts with contents or the environment to help extend shelf life and maintain quality. Moisture-resistant and antimicrobial coatings prevent damage or contamination, while other active solutions like oxygen-absorbing inserts minimize oxidation to extend shelf life.

AI and Automation in Manufacturing

Integrating more AI and automation features into packaging production offers greater efficiency, scalability, and precision, benefiting both brands and their customers. AI-driven quality control measures now use machine learning to analyze images of final products and packaging in real time to assess and improve quality control while minimizing waste. By increasing automation in manufacturing, organizations reduce manual labor, increase production speed, and scale operations without sacrificing quality or accuracy.