Businesses across the board are continuously seeking ways to become more efficient, reduce costs, and work toward more sustainable practices without compromising quality. MOD-PAC is passionate about these initiatives and providing our customers with the products and experience they expect to have when choosing us as their packaging partner. That’s why we’ve committed more than $50 million in machine technology and building upgrades in recent years to raise our customers’ expectations and heighten their experience. From cutting-edge equipment to optimized inventory management to eco-friendly practices, our advanced manufacturing upgrades ensure more innovative folding carton manufacturing solutions.

Equipment Upgrades

Many of MOD-PAC’s recent investments involve machine technology and equipment upgrades. These advancements allow us to keep nearly all of our manufacturing processes in-house. In-house control ensures our customers consistently receive the highest quality products possible with quicker lead times. Recent equipment upgrades include:

Sheeter 7

This machine is one of the fastest and most innovative of its kind. Using this sheeter, our technicians unwind, flatten, and cut all grades of paperboard materials into print-ready sheets in a matter of minutes. At 1,400 meters a minute, we can produce 50,000 sheets an hour, all in-house.

Heidelberg Presses

MOD-PAC takes great pride in our fleet of advanced Heidelberg standard format presses. We use the latest color management spectrophotometers and densitometers to deliver precise, consistent results for our custom folding cartons, even when jobs run multiple on presses simultaneously.

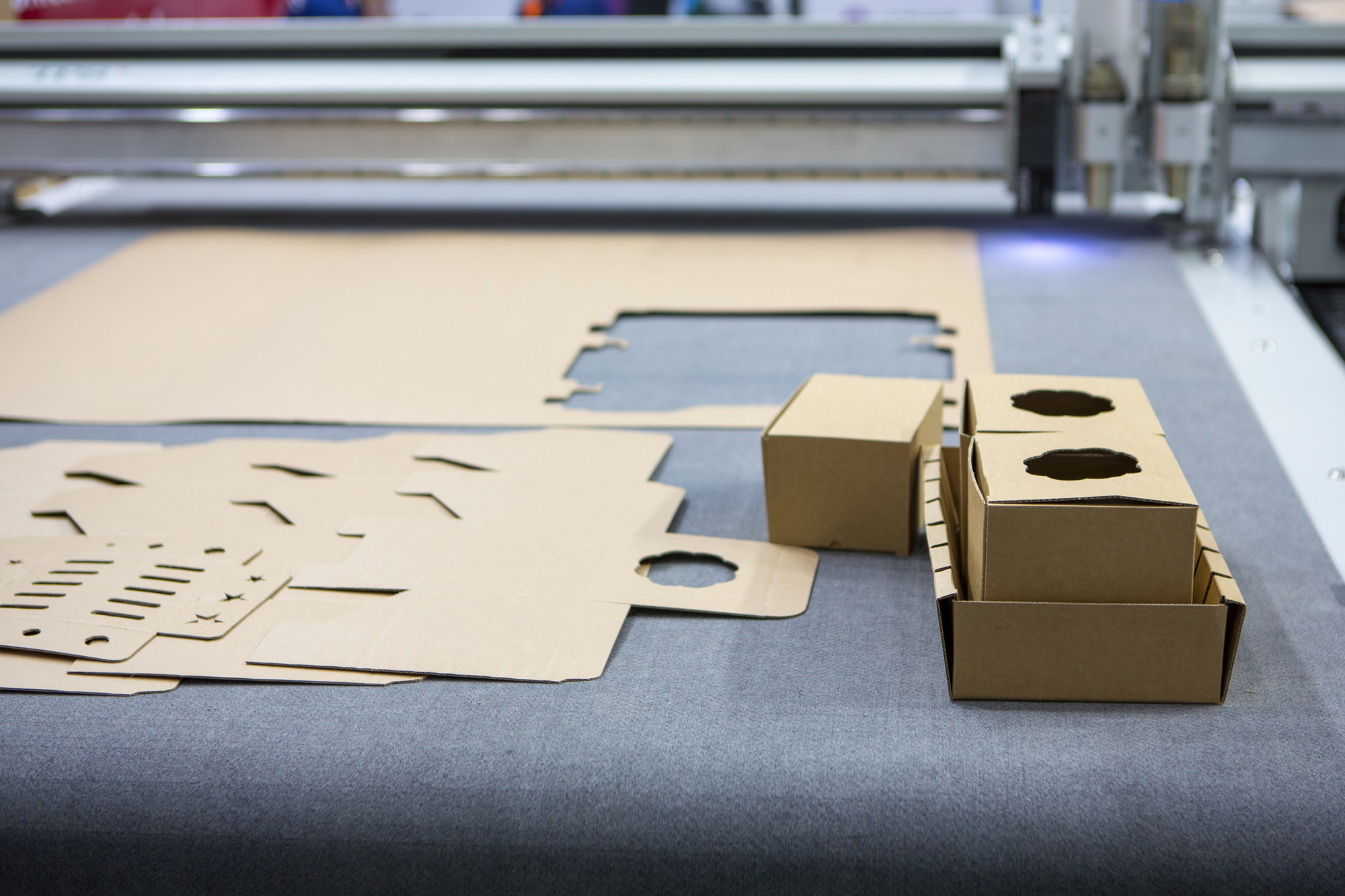

CAD and Die Tooling Systems

Our structural design and die-making teams rely on a state-of-the-art CAD system to design and produce superior die tooling for repeatable results. Our advanced, in-house die tooling equipment is used to create custom tooling and dies which enable our teams to deliver faster turnaround times and higher-quality results for customers.

Inventory Management Upgrades

MOD-PAC’s proprietary make-to-availability (MTA) production strategy solves inventory obsolescence concerns for customers. Through this system, we consistently maintain available stock for our customers through an innovative AI inventory management system. Using these technologies, our team can identify demand trends, sustain appropriate stock levels, and accommodate design or order changes by only printing parts of orders at a time.

Sustainability Upgrades

Both businesses and consumers are making greater efforts to support sustainability initiatives. MOD-PAC shares these values and can help clients meet their sustainability goals. Since investing in volatile organic compounds (VOC) and hazardous waste reduction initiatives, we reduced VOC emissions by 69% and hazardous waste output by 89%. Through recycling programs, we recycle roughly 7,000 tons of paperboard and between 60,000 and 70,000 pounds of aluminum annually. In recent years, we’ve also earned certifications through the Forest Stewardship Council and Sustainable Forestry Initiative for chain of custody and sourcing, meaning all of our paperboard materials are derived from certified sources.